Formula 1: Car

Purpose

Utilize the knowledge of SolidWorks, integration, and manufacturing to CAD a real-life model of a modern Formula 1 car.

Design Process

Ever since, I had training in SolidWorks, I felt that I wanted to retain the newfound knowledge. I thought to myself that I should go BIG and design the 2021 F1 car through SoildWorks from a blank canvas. However, after talking to the suspension lead of Texas Guadaloop for tips, I decided the task was a little too big at the moment to finish within the remaining time of my winter break, so I decided to do a gaming controller. I did make the gaming controller. Learn more about the design process: click here. However, little by little since I am busy, I want to design the F1 car, currently I have made the chassis that I built for a F1 competition with the Circuit of the Americas (COTA). My team and I had the opportunity to gain VIP pass to talk to race engineers, media, and Formula driver.

Overview Process

- Research and design parts of a F1 car

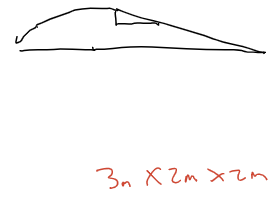

- Hand draw sketched designs with estimated dimensions

- Sketched the CAD models per parts and extrude if needed

- Assemble the F1 car in assembly in SolidWorks

- Completted F1 car :)

Outline of Requirements of the F1 Chassis

&

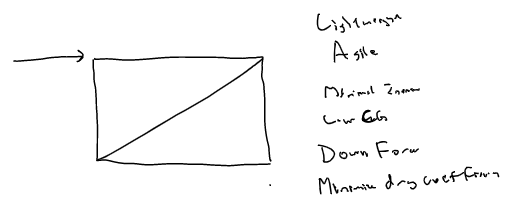

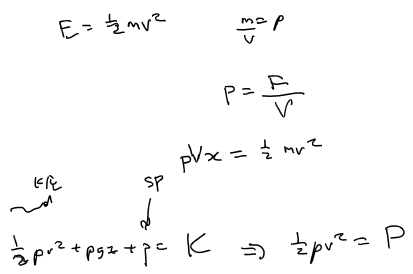

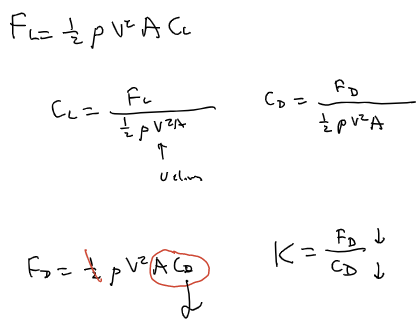

Calculation to Minimize Drag Coefficient

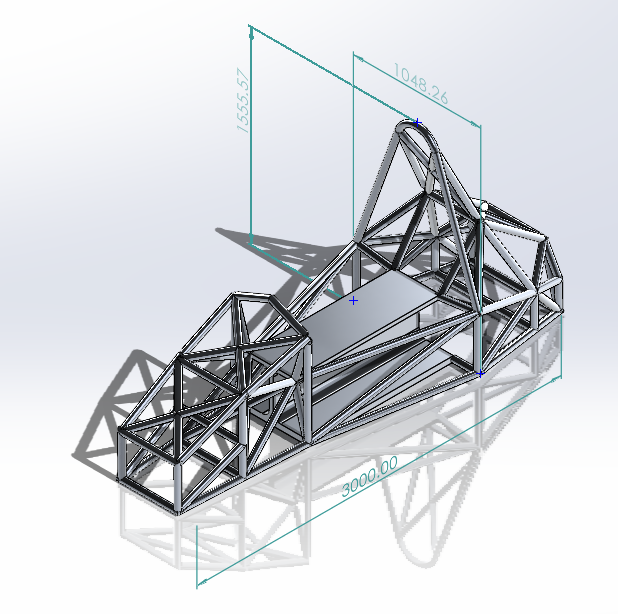

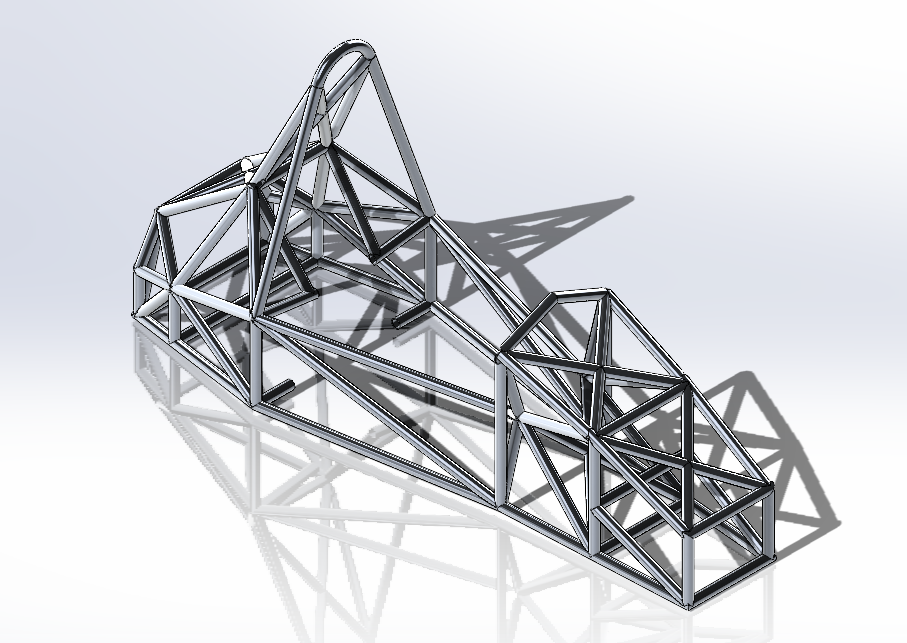

Design: [Chassis] (Finished Oct 16,2022)

- Understand the restriction from the competition by dimensions for the chassis

- Hand draw a sketched design by accounting the forces and aerodynamics of the F1 car

- Sketched CAD model in SolidWorks by using the sketch tool in Solidworks

- Sketched an I-Beam (for uniqueness points and the Gen I hyperloop had an I-beam as a homeage)

- Sketched the chassis surrounding the I-Beam

- Extrude and use a pipe program called weldments

- More detailed in the GrabCAD link below.

Day 1

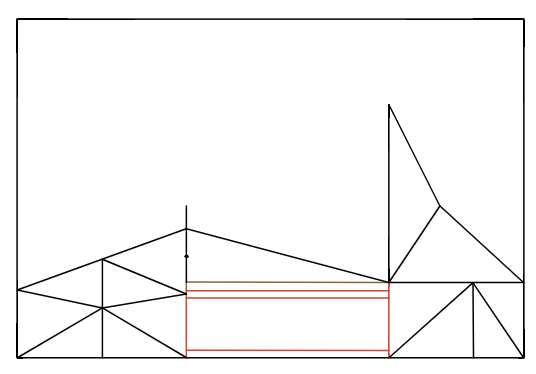

- Focused on the I-Beam and side profile of the F1 chassis

Day 2

- Experienced from others through research

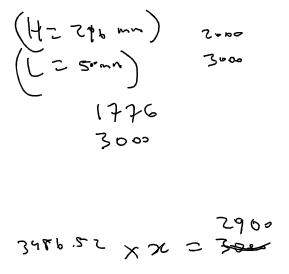

- Communicate with other teammates the dimensions

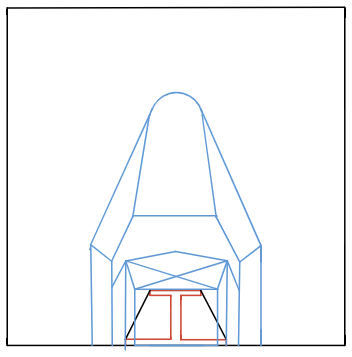

- Drew and design the side and front profile

- Work smarter not harder: Learned about weldments

Front and Back View

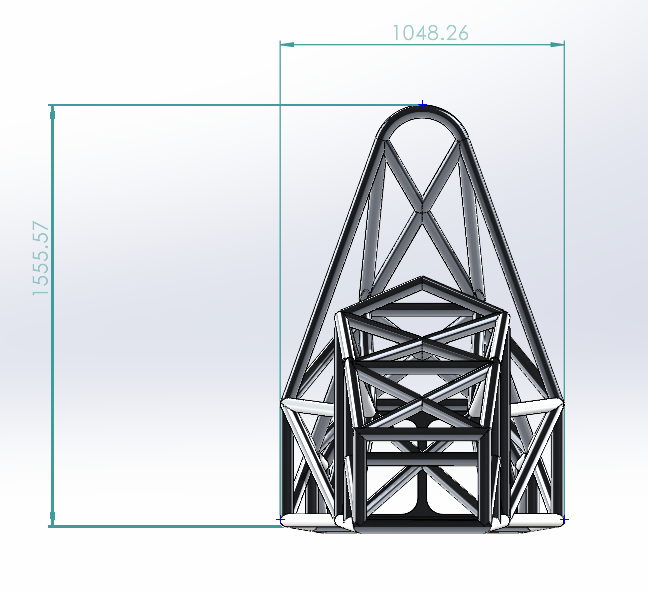

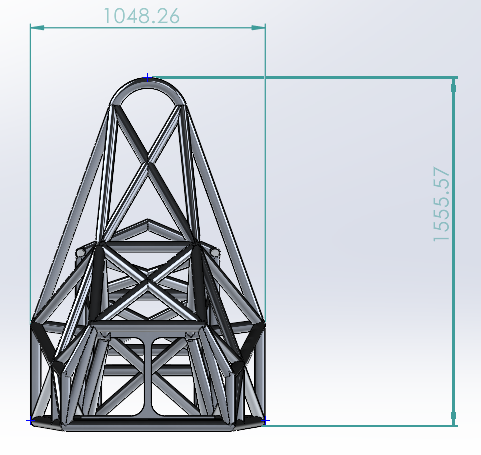

Isometric Views

Skills Learned

- Concepts and body understanding of a F1 car by researching possible stresses encountered

- Learned about weldments

Improvements and Challenges

- A lot of F1 car design are classified, so I had to research mock models and estimate some dimensions to the best of my abilities.

- Learned that can't do weldments in assmebly so had to redo it the F1 chassis to work on part design not assembly. The problem is that we drew the chassis on assembly because we wanted to incorporate the I-Beam into the car.

- Researched: "Why a F1 car doesn't have a backbone chassis?" "How to minimize drag coefficient?"

Overall Thoughts

The chassis was design by a machanical engineering friend and I. It was such a great experience because my friend taught me what to think about of what forces to be applied on the car. Since I love F1, I was able to tell him the type of forces and we drew the design. He helped me on the side view of the F1 car, and I was able to make the front view.

After, we thought about the forces and what is best for the F1, we decided to CAD the car based on the restriction of the

dimensions that we can use for the competition.

After, we thought about the forces and what is best for the F1, we decided to CAD the car based on the restriction of the

dimensions that we can use for the competition.

There was moment that we had to resize the car and use math in order to keep the shape since we didn't account the thickness of the pipe that we added as shown to the right.